- Product Description

-

Order Data

Order Data Order No.

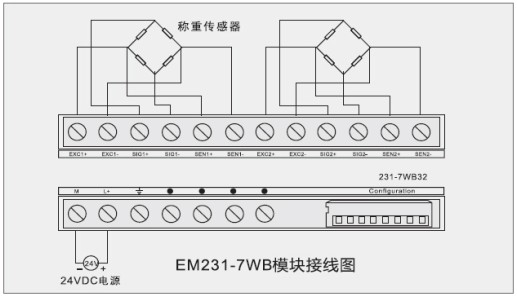

Input signal through dual-channel transducer,16bit,sampling rate20Hz(uni-channel)/10Hz(dual-channel),6 VDC,150mA per channel excitation power output CTS7 231-7WB32

- Technical Spec

-

Performance Parameters

Detailed Information:

Major Features:

· Bus and power supply isolation, high reliability, good anti-jamming capability

· 16bit sampling precision, hardware filter technique, more accurate and stable measured

values.

· Reverse protection and surge absorption function of its power supply makes it adaptable to

severe industrial environment.

Use Standard

· use shielded twisted pair to transmit signals and must have one end earthed

· When the system is in a good state, the earthed end must be connected to the ground

wire, otherwise it is not earthed.

· it is suggested to use Trust PLC library function to read data from weigh module

· Calibration needed when replacing modules

When the system is dual-channeled and has one transducer connected, another transducer should be short-circuited to avoid alarm or shift to uni-channel mode.

Specification

CTS7 231-7WB32

Power Consumption

5W

Power Consumption

+5VDC consumed current

<140mA

L+ consumed current

<100mA

L+ Coil voltage range

20.4-28.8VDC

LED indicator

24 VDC Power Supply Good: ON = no fault, OFF = no power ;

SF: ON=module fault, Blink=input signal error, OFF=normal;Input type

Strain gauge,4 or 6wire mode of connection

Input range

0~1mV/V

0~2mV/V

0~3mV/V

0~4mV/V

Input point

2AI

Isolation Features

field side to logic circuit

500VAC

Field side to 24VDC

500VAC

24V to logic circuit

500VAC

Common-mode input range(from input channel to input channel)

0

Common mode rejection

>120dB@120VAC

Input Resolution

temperature coefficient null point

≤±0.1uV/K

Principle of measurement

Sigma-Delta

length of conducting line to transducer

Maximum 500 meters

Noise suppression

85db@50Hz/60Hz

Data word format

Voltage:0 to+32000

Resolution

16 bits

Intrinsic error

0.05%Fs

Repeatability

0.1%Fs

Related Information

Library function of weigh module TrustPLC 231-7WB32.

- Installation

-

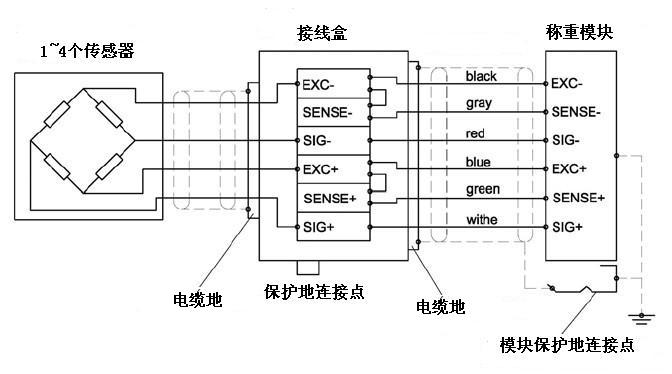

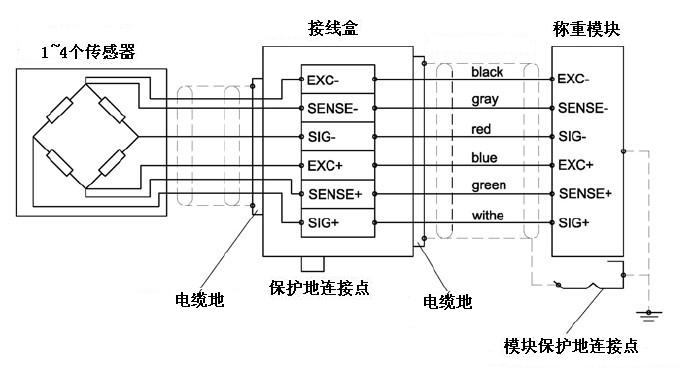

Terminal Connection

Weighing module which is a measuring module of high-precision requires reliable measuring low signal level (about 1.5uV). Thus, to make sure it works, it is important to choose appropriate

assembly and cable connection.

While connect weighing transducer, following rules should be obeyed.

· If more than one transducer is going to be connected (if they are weighing transducers,

they must be parallel connected), one junction box must be used. If the distance between

weighing transducer and module or between weighing transducer and junction box is

longer than the length of available cable of weighing transducer, a dedicated extension box

Should be used.

· Shield of cable should always reach as far as to cable gland of junction box or extension box.

· Use stranded wire to connect cable in certain circuit and keep it shielded.

---transducer wire SEN+/SEN-;

---measuring voltage coil SIG+/SIG-;

---supply voltage coil EXC+/EXC-.

·Shielded wire must be joint with shield connector.

Four- Wire connection

When connect four-wire transducer, please make sure that EXC with SENS, EXC with SENS- are short

circuited. Otherwise, the module may not work normally.

2、Six-wire connection

3、Module Connection Diagram

DIP Switch Setting

DIP Switch Configuration

Switch 1、2、3、4、5、6

setting

function

SW1、2

01

Choose 1mV/V transducer

00

Choose 2mV/V transducer

(default)

10

Choose 3mV/V transducer

11

Choose 4mV/V transducer

SW3

0

Choose dual channel working

model (default)

1

Choose uni-channel working

model

SW4

0

Choose filter1(default)

1

Choose filter 2

SW5、6、7、8

00

Spare, reserved

Remark:

Ø Default state:000000

Ø Which filter to be used is determined by software according to need of debug.